Free Standing Jib Cranes For Sale, Tailored freestanding jib Designs

Free standing jib crane for sale.Different mounting types for your freestanding jib selection. Economical jib cranes for your workshops & workstations.

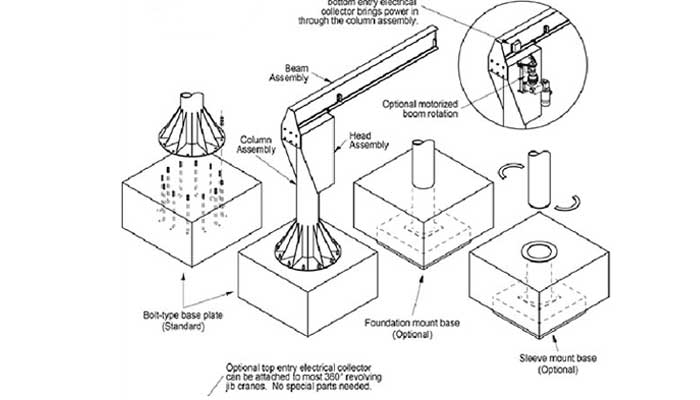

What are freestanding jib cranes?A freestanding jib is a jib system with few placement constraints. These jib cranes can be installed indoors or outdoors, in an open area, or beneath other heavy duty overhead crane systems. These freestanding jib cranes come in a variety of mounts based on what services you want them to provide:Types of free standing jib cranes based on mounting types

Base-plate mounted freestanding jib cranes: Installers place a jib crane with a base-plate mount by bolting it into a reinforced concrete foundation and using gussets to keep it stable.

Overview of base plate mounted free standing jib cranes

Freestanding jibs from EOTCRANEKIT.COM can be installed almost anywhere, including outside. These freestanding foundation-mounted jib cranes have higher capacities, longer spans, and greater rotation than our wall-mounted jib cranes:

Base-plate mounted freestanding jibs have the following characteristics.

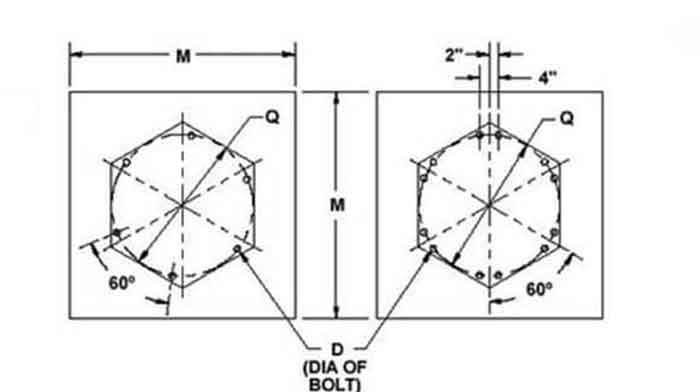

The hexagonal base plate is secured to a prescribed reinforced concrete foundation with anchor bolts, and the pipe mast's connection to the hexagonal base plate is reinforced with six equally spaced gussets.

Base plate mounted free standing jib cranes

- Crane rotation: 360 degrees

- Capacity: up to 16 tons

- Spans: up to 50'

- Height: up to 40' from floor to underside of boom

EOTCRANEKIT.COM Freestanding crane jibs have greater capacities and spans than wall-mounted cranes. These foundation-mounted cranes can be installed nearly anywhere.

Overview of foundation mounted freestanding jib cranes

Foundation mounted freestanding jib cranes: This is the most permanent type of freestanding jib crane. It does not require gussets, allowing full use of the work area around the mast. To stabilize it, the installers pour two separate reinforced concrete foundations instead of gussets. A metal plate at the base of the mast of a foundation-mounted jib crane is also installed on top of the first pour reinforced concrete foundation.

Foundation mounted freestanding jibs from EOTCRANEKIT.COM can be installed almost anywhere, including outside. These foundation-mounted, freestanding jibs outperform our wall-mounted jib cranes in terms of capacity, span, and rotation:

- Foundation mounted freestanding jibs have no gussets, which frees up space at the crane's mast's foot.

- A square steel plate is welded to the bottom of the mast.

- The plate anchors the mast to the first-pour concrete footing and positions and plumbs it. The second pour supports the mast.

Foundation mounted freestanding jib cranes

- Crane Rotation: 360°

- Capacities: up to 15 tons

- Spans: up to 50'

- Heights—floor to underside of boom: up to 40'

EOTCRANEKIT.COM Crane freestanding jibs provide higher capacities and longer spans than wall-mounted cranes. These foundation-mounted cranes install almost anywhere.

Foundation footing design of freestanding jib cranes

Sleeve-insert mounted freestanding jib cranes: Businesses prefer sleeve-insert mounted jib cranes because they are more flexible than foundation mounted. A sleeve-insert mounted jib crane, like the foundation mounted, does not use gussets, allowing the entire work area around the mast to be utilized. The installers begin by installing a sleeve insert into a first pour reinforced concrete foundation. A second pour reinforced concrete foundation is then used to reinforce the sleeve insert. The mast is then inserted into the sleeve insert and properly aligned using wedges that are welded to the sleeve. A sleeve-insert mounted jib crane enables crane relocation without causing damage to the mast.

Floor mounted freestanding jib cranes need to be mounted properly or the jib crane will collapse, resulting in damage to the load as well as human injury or death. A small selection of freestanding jib cranes can be mounted straight to a 6" reinforced concrete floor, the industrial building standard. The rest of the floor-mounted freestanding jib crane range must have a square of factory floor torn up and a specially-designed concrete footing installed.

How do I determine if my freestanding jib crane needs a foundation? Plan on needing a foundation unless your jib crane engineer tells you specifically otherwise. How do I know how big to make that pillar foundation? EOTCRANEKIT.COM Hoist and Crane will supply you with a drawing showing the length, depth, and width of the pillar foundation required, as well as any reinforcement required and the anchor bolt placement. EOTCRANEKIT.COM Hoist and Crane also offers a kit consisting of anchor bolts, anchor bolt template, and early kit shipment so the customer can set the jib crane foundation including anchor bolts before the actual freestanding jib crane arrives.

freestanding jib crane foundation footing design

How to install a freestanding jib crane to the floor?A freestanding jib crane is anchored to the foundation or wall with anchors that can be ordered with the freestanding jib crane or purchased by the customer at a local bolt or supply house. It is important that the freestanding jib crane be anchored to a proper concrete footing or properly engineered wall or building column. Bolts alone cannot anchor most freestanding jib cranes into industry standard 6" reinforced concrete floor. The floor will buckle, the jib crane will collapse, loads and/or people will be hurt. If you have any questions, please call our office first or reference your owners' manual supplied with every freestanding jib crane. A freestanding jib crane is easy to install provided the directions are followed carefully. Most customers prefer to install their own freestanding jib cranes but installation is available through freestanding jib crane Outlet Installation.

Bolt for fixing freestanding jib crane on the floor

Overview of sleeve insert freestanding jib cranes

Sleeve insert freestanding jibs from EOTCRANEKIT.COM can be installed almost anywhere, including outside. These foundation-mounted, freestanding jib crane jibs outperform our wall-mounted jib cranes in terms of capacity, span, and rotation:

- The advantages of sleeve insert mounted freestanding jibs include the ability to relocate the crane without damaging the mast.

- There are no gussets, which frees up space at the base of the crane's mast.

- The sleeve is welded to a square steel plate, which anchors to the first-pour concrete footing and positions and plumbs the sleeve.

- The sleeve is supported by the second pour.

- The mast is inserted into the sleeve, leveled with wedges, and welded into position.

Freestanding jib cranes with sleeves mounted floor design

- Crane rotation: 360 degrees

- Capacity: up to 156 tons

- Spans: up to 50'

- Height: up to 40' from floor to underside of boom

EOTCRANEKIT.COM Freestanding crane jibs have greater capacities and spans than wall-mounted cranes. These foundation-mounted cranes can be installed nearly anywhere.

Types of freestanding jib cranes based on jib cantilever designs

I beam freestanding jib cranes

Ergonomic Partners handles Structural I-beam jib cranes and free standing freestanding jib cranes for all your work cell lifting applications. Whether you need a lightweight workstation jib or a structural system, Ergonomic Partners has you covered from 100 pound capacity to 5 tons. Heavy loads have never been easier to move with the ability to motorize the jib rotation, trolley and hoist.

Tie rod cantilever free standing jib cranes

Tie rod jib crane crane for sale good price. 1 ton - 10 ton tie rod wall mounted jib crane & 0.25 ton -2 ton light duty portable tie rod jib crane. Contact us to get your customized tie rod jib crane at cost-effective jib hoist price.

Kbk cantilever freestanding jib cranes

Light jib crane, kbk crane design, low deadweight, easy position, to improve productivity & safety. Light, easy jib crane 125kg, 250kg, 500kg for sale.KBK Jib Crane & Low Deadweight Jib Crane for sale good price.

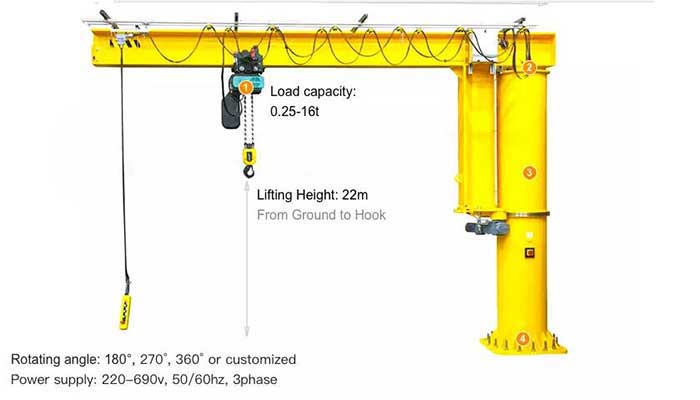

Types of free standing jib cranes based on rotating designs

A freestanding jib crane will always rotate which can be grouped into manual rotating and electric rotating. Most freestanding jib cranes will also have a third motion, that of traverse: The load will be able to traverse the cantilever from the center of the circle to the edge of the circle created by the jib as the jib rotates.The freestanding rotating cranes are able to rotate the jib arms with the loads to 180 degree, 270 degree and full 360 degree, which can be a compact and reliable lifting crane solution for various workshops and production lines.

Freestanding jib cranes typically have a hand-powered rotation and traverse motion, while it is common to see either electric-powered or hand-powered lift motion.

Hand-powered rotation and traverse motions are accomplished through push/pull, while hand-powered lifting is accomplished through a chain similar to that of a non-powered garage door. For those looking to buy a lifting crane, almost all freestanding jib cranes have electric rotation and traverse options.

Manual rotating free standing jib cranes

Electric rotating free standing jib cranes

What rotation options are available on a freestanding jib crane?

A freestanding jib crane covers an area by rotating rather than moving. Most customers prefer to cover as much ground as possible with a single jib rotation. Some customers, on the other hand, may prefer to limit the rotation of a freestanding jib crane. For a small additional sum, rotation stops can be installed on most floor-mounted freestanding jib cranes.

For example, in a machine shop with a computerized machining center next to a freestanding jib crane, the buyer does not want the freestanding jib crane to be able to rotate into the neighboring CNC machine. Furthermore, depending on the rotation types, some crane buyers will require different electrification options, such as a "top entry collector" or "bottom entry collector."

The jib crane engineer will make this decision because each option has a more appropriate application. Because these collectors allow unlimited rotation in one direction, they help make jibs more flexible.

Finally, the boom or cantilever itself can be motorized. This is a costly option that is typically used in heavy duty jib crane or high-capacity jib crane applications. Powered rotation jibs are commonly used in pipe pit-casting applications; in fact, the first overhead crane in the world was a motorized pit-cast freestanding jib crane in Birmingham, Alabama.

Benefits of freestanding jib cranes over wall- mounted jib cranes

Freestanding jib cranes have several advantages over wall-mounted jib cranes. Among these advantages are:

- Floor-mounted jib crane systems can rotate 360 degrees, giving them more range than wall-mounted jib cranes, which can only rotate 180 degrees.

- Higher capacities: freestanding jibs with capacities of up to 16 tons are available.

- Longer spans: Various types and series of freestanding jib cranes are available in longer spans than our wall-mounted jib cranes, depending on capacity.

How to select the right type of freestanding jib crane?

EOTCRANEKIT.COM not only offers different types of cranes but also crane services to make your crane more efficient. For your convenience, jib crane manufacturing engineers have provided a series of frequently asked questions and answers on freestanding jib cranes, pillar jib cranes, and floor jib cranes. The goal of EOTCRANEKIT.COM is to be your professional freestanding jib crane expert on the side.

Freestanding jib crane drawing

What dimensions are important when purchasing a freestanding jib crane?

- Lifting capacity of a freestanding jib crane. The weight of the heaviest load to be lifted, or the lifting capacity of the freestanding jib crane, is one of the most important dimensions to consider when designing a jib crane.

- Jib crane hoist travel distance. The jib hoist travelling length, which is also an important dimension, is how far the electric hoist can travel along the jib crane arm or the jib cantilever.

- Lifting height of a jib crane: How high must the load be lifted? That is the jib crane's lifting height.

There is also a requirement for some design margins to allow jib crane equipment to fit in the space. Most freestanding jib cranes will have an electric hoist that is approximately 24" tall and a cantilever that is approximately 12" tall. That is, the lowest obstructions above the required load height are 42", which includes the electric hoist, cantilever, and the required 6" safety margin.Furthermore, because the load cannot be carried all the way to the edge of the jib crane cantilever, a 3" gap must be left at the moving end of the cantilever and a minimum 12" gap must be left at the stationary end of the cantilever to accommodate the crane pillar, bearing, hinge, wall, and any other obstructions.